How do you approach hull care? As we saw in our post, Hull Smoothness – What Matters for Speed?, hull smoothness matters but only to a point. In this post, we’ll cover how to achieve a smooth hull and ways to protect the finish to minimize ongoing maintenance.

The variety of products, terminology, and scientific-sounding claims makes this topic confusing. To clarify and simplify, we consulted dozens of sources. While there’s lots of content available about automobile paint finishing, some of it doesn’t apply to gelcoat. Gelcoat is harder than automotive paint and needs tougher rubbing compounds. Also, auto geeks are more interested in varieties of shine rather than low friction.

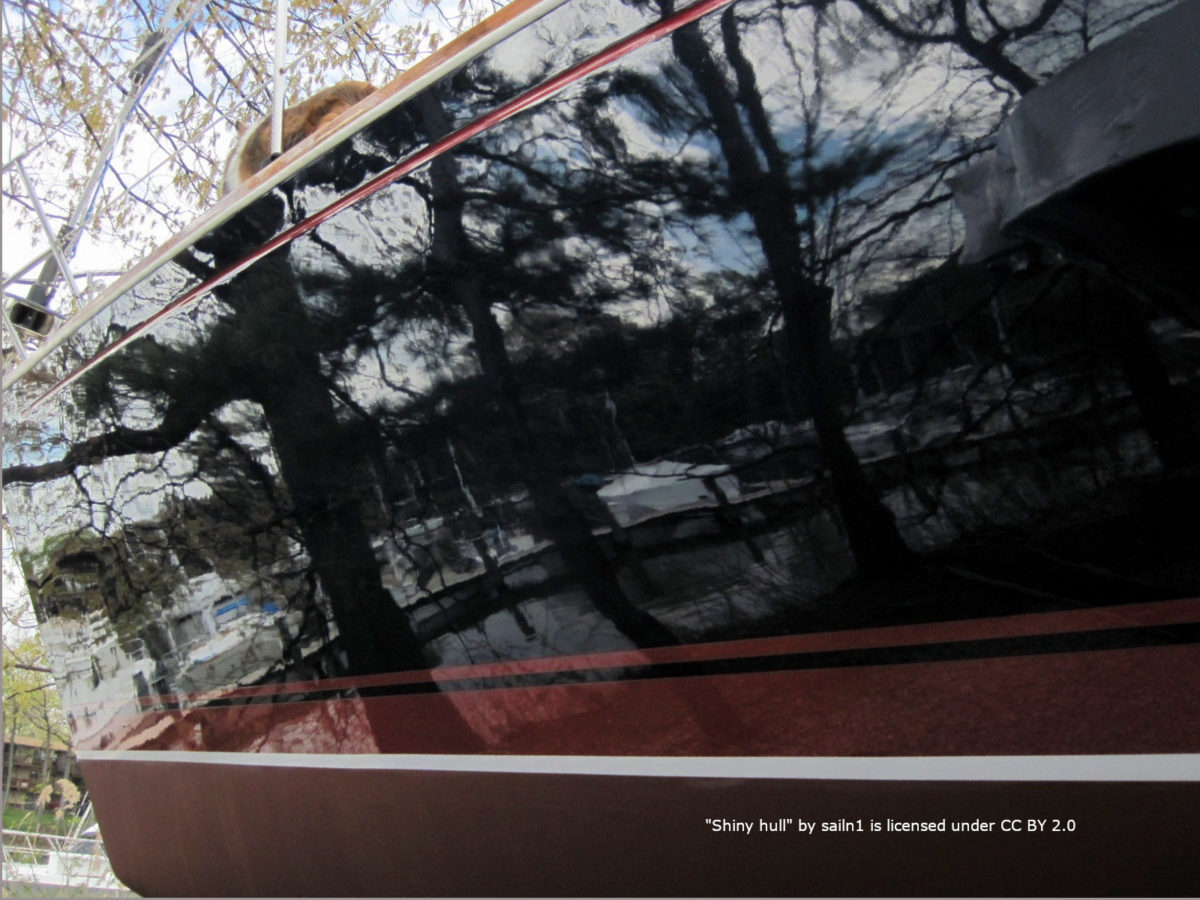

Appearance of a Smooth Hull

Let’s start by sorting out some concepts and misconceptions about appearance.

Smoothness vs. Gloss (shininess)

A very smooth surface produces a clear and bright mirror-like reflection, like the photo above. This is called specular gloss. Slightly rougher surfaces may reflect a lot of light, but the gloss will be more diffuse, like a glow or sheen. Some waxes applied over smooth surfaces will produce a slightly rougher surface, evidenced by a fuzzier reflection. More on gloss at Wikipedia.

Water Repellence – Beading and Sheeting

Auto detailing sites spend a lot of time discussing beading and sheeting. Surfaces that bead water are said to be more hydrophobic (repel water) than surfaces that sheet water. However, whether your hull beads or sheets water has little effect on skin drag, since the hull is immersed in water. The no-slip condition we discussed in the hull smoothness post still applies.

Beading and sheeting do indicate a degree of hull protection. If your hull beads or sheets water, it will shed dirt and water to prevent film and spots. If not, it’s probably due for some attention.

Hull Care – Achieving Smoothness

Cleaning

The most important thing you can do is keep your hull clean. Road dirt, water scum, and pollutants from the air will destroy the smoothness.

To clean gelcoat, use the least aggressive cleaner that will do the job. Here are typical cleaning methods from least to most aggressive

- Dry with a soft towel after racing. This will get scum off and prevent hard water stains.

- Dish soap, such as Dawn. Dish soap is mild and works well on grease or other organic substances. However, it will also remove wax. Since waxing your hull is not recommended, this is not a problem. Dish soap can dull a car’s finish but is not likely to dull gelcoat.

- Boat soap – many brands. These are mild cleaners. Some brands are formulated to not remove existing wax.

- Vinegar or lemon juice. These are mild acids that are good at removing hard water stains, with little effect on the surface.

- Acetone is a strong organic solvent, good for removing tougher organic/paint stains. Most sources say that acetone will not harm fully-cured gelcoat. However, avoid skin exposure and inhalation of fumes.

- Stronger acid-based cleaners, such as Zing, On & Off Hull/Bottom Cleaner, or even ordinary toilet bowl cleaner. These contain oxalic, phosphoric, and/or hydrochloric acids, and may be needed for heavy staining. These cleaners will open the pores in the gelcoat, leading to increased oxidation over time.

- For salt water or brackish water, you must rinse the boat thoroughly after sailing. Consider using a salt remover, such as Salts Gone. A mix of vinegar and boat soap will also work.

- Magic eraser. Effective, but abrasive – will likely dull the finish. Use on non-skid, but not on hulls.

Polishing, Compounding, and Wet Sanding

The factory finish is normally very smooth and shiny. Better yet, according to Paul Grimes, untouched gelcoat has a thin, resin-rich layer on the outside that helps to protect it from weathering. So, avoid doing anything to remove this layer. If you keep the hull clean and out of the sun, it likely will stay smooth and retain its original shine for several years.

Eventually, the hull will start to lose its shine, due to oxidation from sun and air. Then you will want to polish, compound, or wet sand the hull, depending on the degree of oxidation. Use the least aggressive treatment necessary.

- If the hull is shiny when clean and dry, don’t bother.

- If it looks shiny wet, but not dry, try polishing.

- If dull both wet and dry, or rag is chalky, try compounding.

- As a last resort, use wet sanding.

Polishing

Polishing is the least aggressive smoothness restorer. A polishing compound contains extra fine abrasive and is only useful for zero to light oxidation.

Most polishes also contain a wax or a polymer sealant with a hydrophobic, low-friction material such as Teflon. Stay away from polishes that contain traditional (Carnauba) wax. For a fine polish without waxes or sealants, try 3M Marine Finesse-It II Glaze. See the section on Sealers and Coatings for polishing products that contain sealers.

Apply these by hand or use an electric buffer and a polishing pad.

Compounding

Compounding removes light to heavy oxidation. Compounding is best done by a pro.

If you’re willing to spend some time you can compound a boat, following instructions like those in How to Buff Your Hull the Right Way – Power and Motor Yacht. You must use the right tools and products: electric buffer (variable speed orbital or dual action), compound (marine compound with the desired grit), buffing pad (wool for medium-heavy oxidation, foam for polishing). Also use the right speed and pressure to heat the gelcoat and close the pores.

Wet Sanding

Wet sanding lets you achieve any degree of final smoothness – from 400 grit to 2000+. Wet sanding is a last resort since it removes gelcoat aggressively. Most sailors wet sand to a 1200-1500 grit finish, then follow up with polishing. See Learn How to Wet Sand your Boat with Shurhold – from Sail World.

Hull Care – Protecting the Finish

Once your hull is smooth, it makes sense to protect it. Gel coat is porous and thus is prone to oxidizing and taking on dirt, scum, and stains. Ideally, you want to prevent these without affecting the gelcoat’s smoothness. Many available products provide protection but don’t preserve the smoothness you worked so hard to get. You also want the protection to be durable, but you have limited options here.

Protection products include waxes, sealers, and coatings.

Waxes

Wax is a generic term, used as a catchall because it is familiar: To many people, wax is anything that protects the surface and increases shine. For this article, we will speak of traditional wax, which is any product containing natural wax. Products containing Carnauba are the most common.

None of our sources recommend traditional wax for the hull. Counterintuitively, traditional wax will decrease the smoothness of a well-prepared hull.

To remove existing traditional wax, use a dish soap such as Dawn, or a wax remover. Wax removers are marketed as effective without affecting the underlying surface.

Sealers

Sealers are usually polymers, either water or solvent based. Sealers are easier to apply than coatings but are less durable.

Sealers for racing boats often contain polytetrafluoroethylene (PTFE), known by its brand name (Teflon). PTFE is known for its low-friction properties. Here are some recommended sealers.

- McLube Hullkote Speed Polish. Citrus based polish removes light oxidation. Contains PTFE. Claims to last for 20 days of hard sailing, more with two-three coats. Easy to apply. Reviews are generally very positive, but mixed about durability.

- McLube Antifoul Alternative. Citrus-based polish. Biodegradable. Contains PTFE. Easy to apply, Used by boats in distance races.

- StarBrite Marine Polish. Polish containing PTFE (spelled PTEF on the product). Easy to apply. Less expensive than McLube products. Fewer reviews but reviews are positive. Durability is not likely to be any better than the McLube products.

- Rejex High Gloss Finish – does not mention PTFE as one of the ingredients. Claims to be long lasting. Reviews from auto owners are mostly positive about durability.

Coatings

Coatings are polymers formulated for hardness and durability. Ceramic coatings use some form of silica (silicon dioxide) as the base material.

Here are key points about ceramic coatings:

- Expensive. Anywhere from $200 and up for the product alone.

- Significant prep time. Manufacturers recommend washing, compounding, polishing, and surface decontamination before applying the coating. Two coats are recommended.

- Durable. While not permanent, a well-applied and maintained ceramic coating could last up to three-five years.

- Easy to maintain. Rather than re-sealing frequently, all you do is keep the hull clean and apply spray-on maintainer periodically. One sailor reports that he removes scum with a quick wipe of a rag.

What Do Most Sailors Do?

the International Lightning Class Association shows the results of a poll of Lightning class experts on their approach to hull care in What is a Fast Finish, or The Bottom Question.

Some sailors are trying ceramic coatings. Thanks to Sean Bradley for his input on this topic.

Whatever you do, keep things in perspective. If your hull is fair, clean, and smooth to 400-grit equivalent, you’re not going to lose races because of skin friction.