If you have an MC Scow numbered 2476 or earlier, you may have had the lee boards stick in the up position, making it difficult to release them for a tack. In this article, we discuss the causes and solutions for MC boards sticking.

Sticking in the up position usually happens because the board has been pulled up with too much force, wedging it into the fiberglass in the deck above the board trunk. It can also happen because of a weak bungee cord or an out-of round pivot hole in the board itself.

I struggled with this problem, addressing the weak bungee cord and out of round board hole first. Then I tried gluing a hard rubber stop inside the front of the board trunk to prevent raising the board too far. This worked marginally, but was difficult to adjust and didn’t last long.

Adjust the Length of the Line Between the Board and the Block

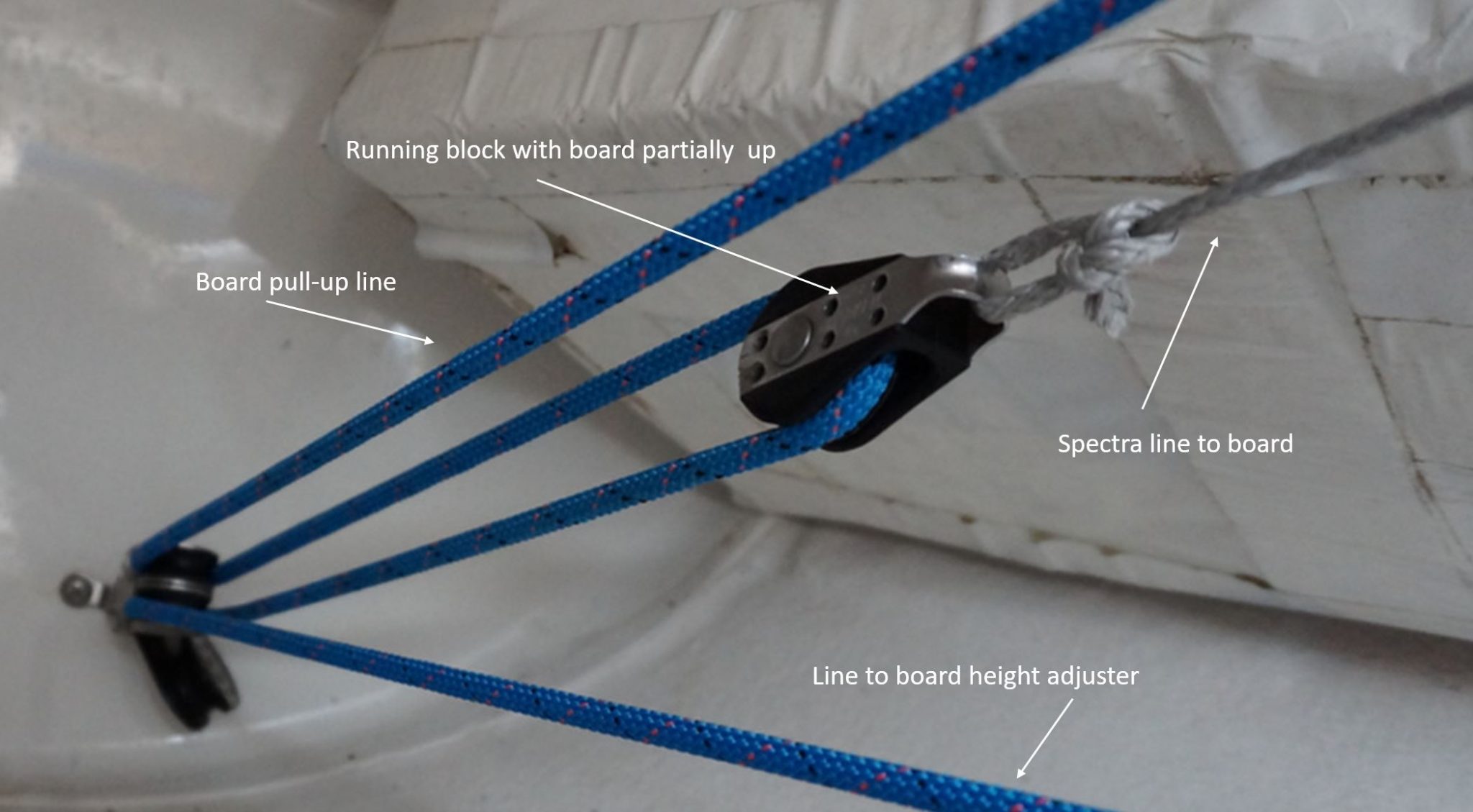

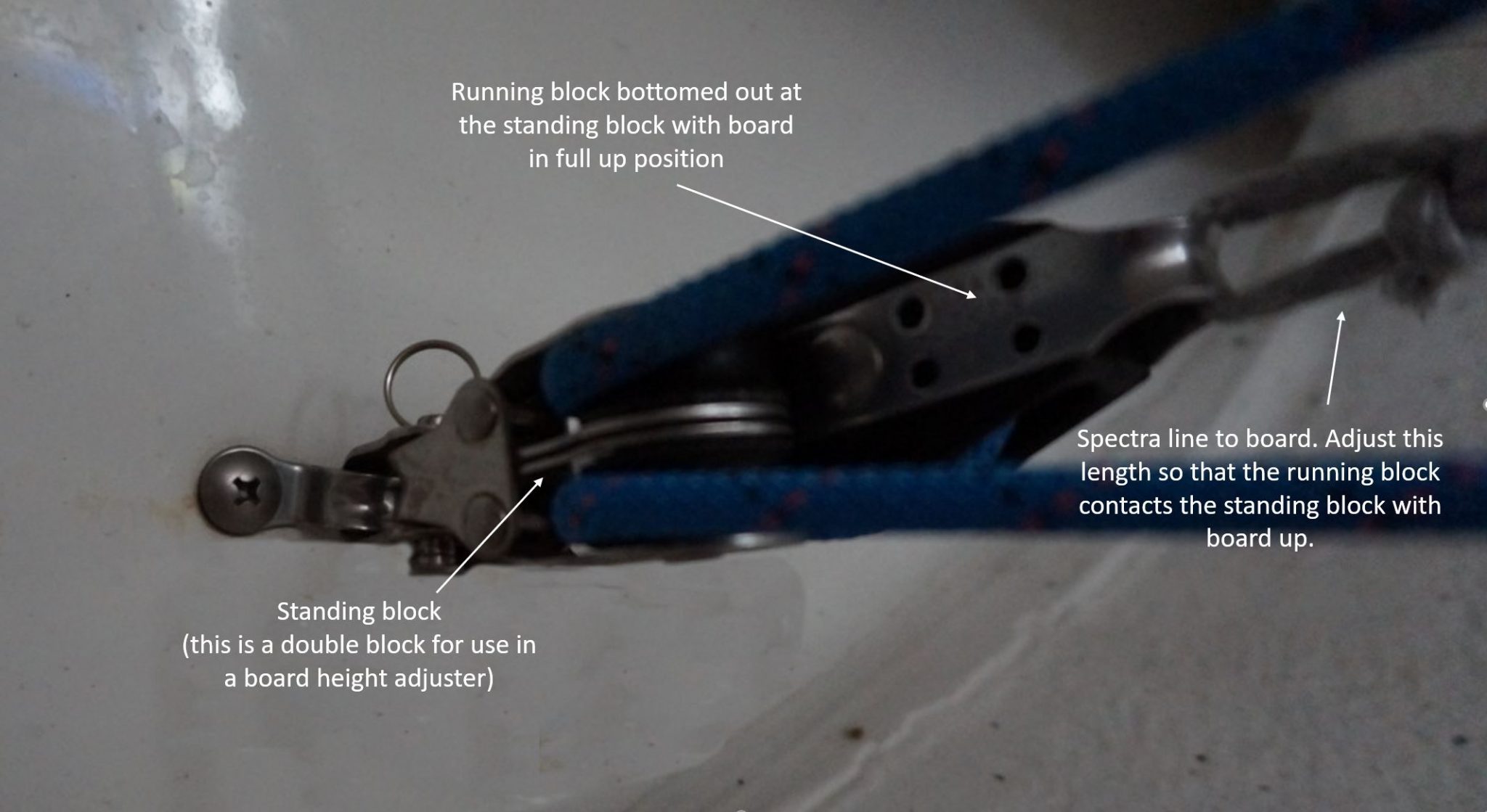

The folks at S&R Marine in Pewaukee, WI showed me a better solution. They adjusted the length of the spectra line attached to the board so that the running block bottoms out against the standing block when the board is precisely in the full up position. Now the boards don’t stick, even if I get a little overzealous and pull them up too hard!

Below are two photos of my board pull-up lines: first, an overview with the board partially up and second, with the board fully up showing the running block bottomed out to prevent raising the board too far.

You can do this yourself with these steps:

- Hold the board in the full up position with the pull-up line released.

- One way to hold the board in place is to wedge a tapered piece of wood between the board and the board trunk.

- Full up position is where the bottom of the board has just disappeared into the board trunk.

- Release the board pull-up line with the board release line

- Replace the spectra line between the board and the running block with a length of spectra slightly longer than the distance between the standing block and the attachment point on the board.

- Tie the spectra line to the running block so that the running block just contacts the standing block with the pull-up line taut.

- Free up the board and check that it just disappears into the board trunk when the pull-up line reaches the end of its travel. Re-adjust the spectra knot as necessary.

- Cut off any excess spectra line.

Other Potential Causes and Solutions

There are two other potential causes of the board sticking in the up position:

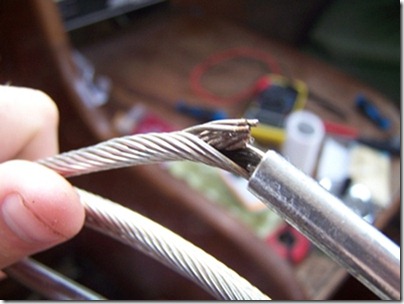

- The shock cord that pulls the board down have lost some elasticity. Replace it with a fresh one.

- The pivot hole in the board might be out of round from wear, causing more resistance to pivoting. The MCSA website has an article by Herman van Beek on how to correct this condition using a replacement set of bushings.